- Performance: Up to 1500VDC / 1000A / 16kA Breaking Capacity

- Speed: <2ms Disconnection (Internal & External Trigger)

- Safety: UL 94 V-0 Flame-Retardant Housing

- Service: Fast Quotes (8h) · Ready-to-Ship Samples

Trusted by Industry Leaders

Pyrofuse for ESS and EV

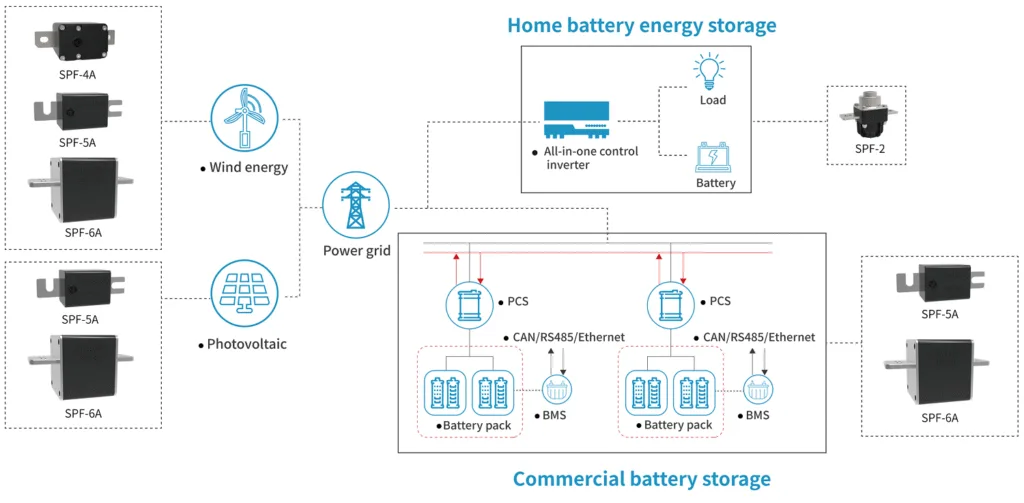

Wind power, Solar & Energy Storage System Fuse Application Scenario

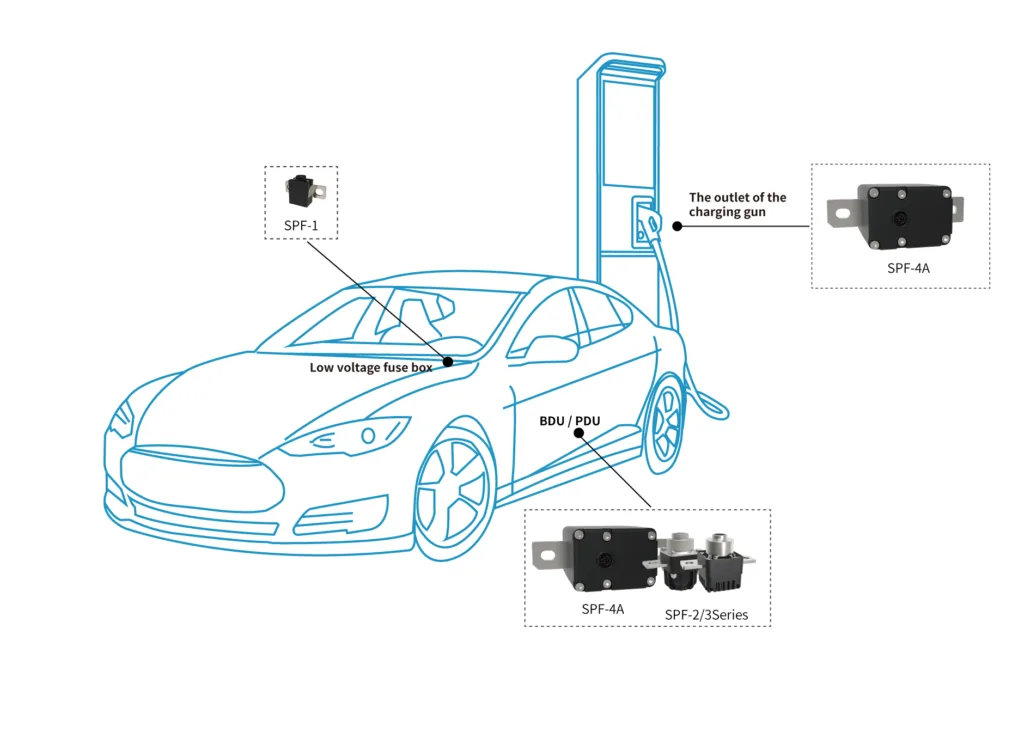

EV & Charging Station Fuse Application Scenario

Find the Right Pyrofuse for Your System

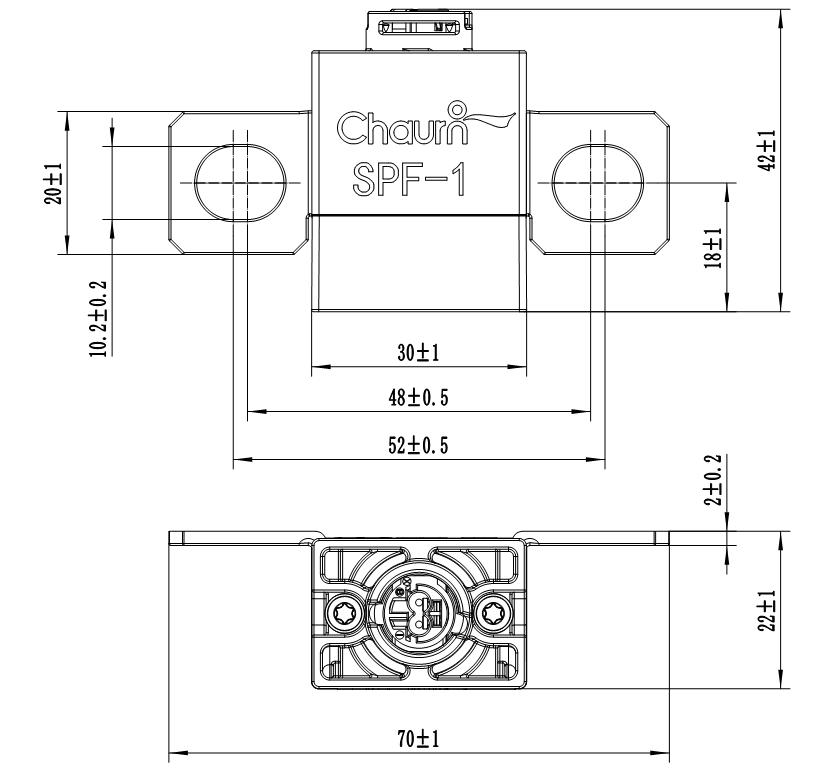

SPF‑1

Rated voltage: Up to DC 150V

Rated current: 300A

Breaking capacity:

32V/2kA/60μH,

150V/1.2kA/60μH

Breaking time: <2ms

Trigger method: External Trigger

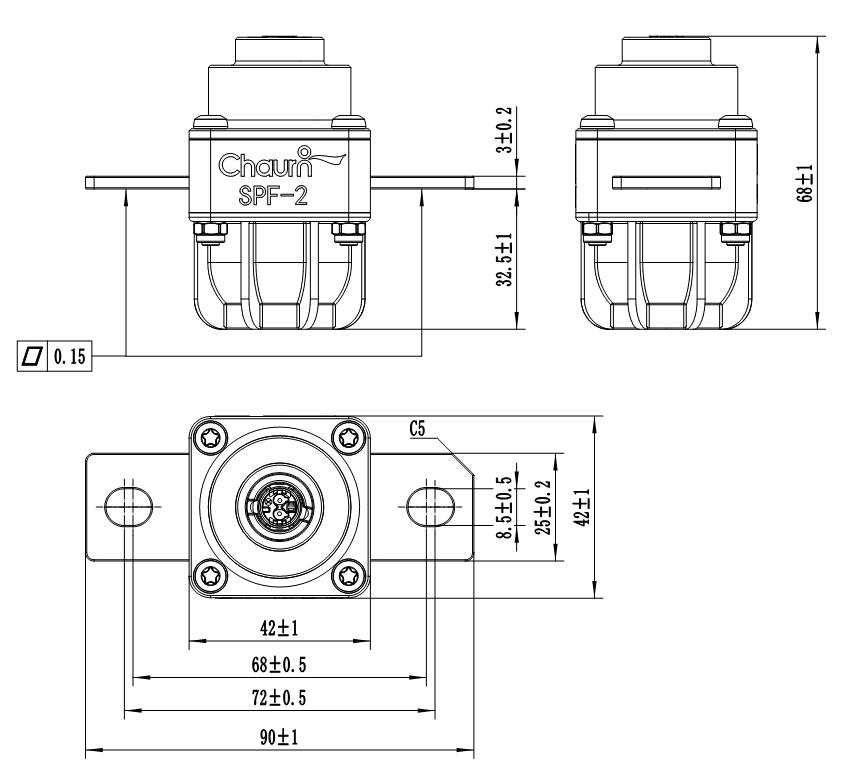

SPF‑2

Rated voltage: Up to DC 500V

Rated current: 400A

Breaking capacity:

400V/10kA/15μH

500V/5kA/20μH

Breaking time: <2ms

Trigger method: External Trigger

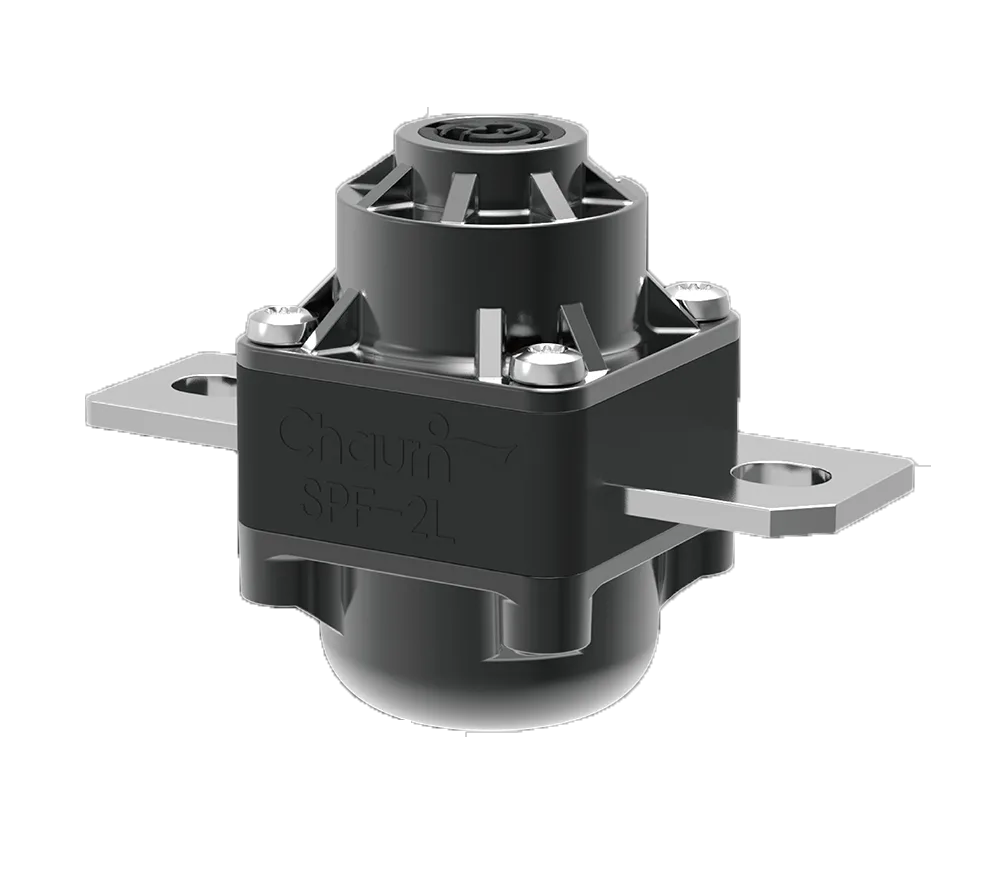

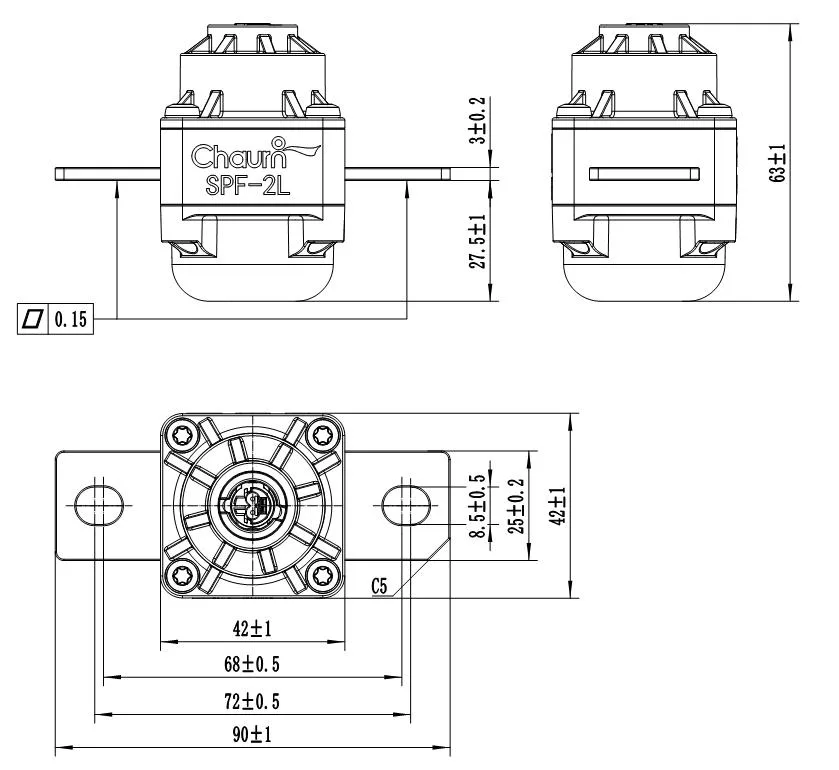

SPF‑2L

Rated voltage: Up to DC 930V

Rated current: 400A

Breaking capacity:

930V/12kA/15μH

500V/13kA/15μH

Breaking time: <1ms

Trigger method: External Trigger

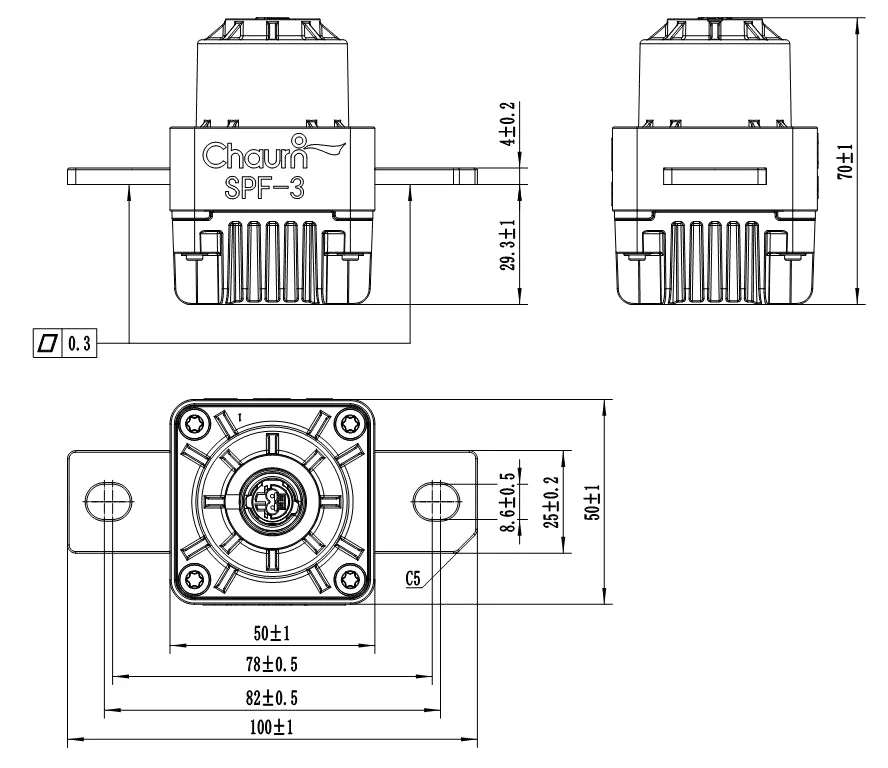

SPF‑3

Rated voltage: Up to DC 1000V

Rated current: 400A

Breaking capacity:

1000V/16kA/20μH

Breaking time: <3ms

Trigger method: External Trigger

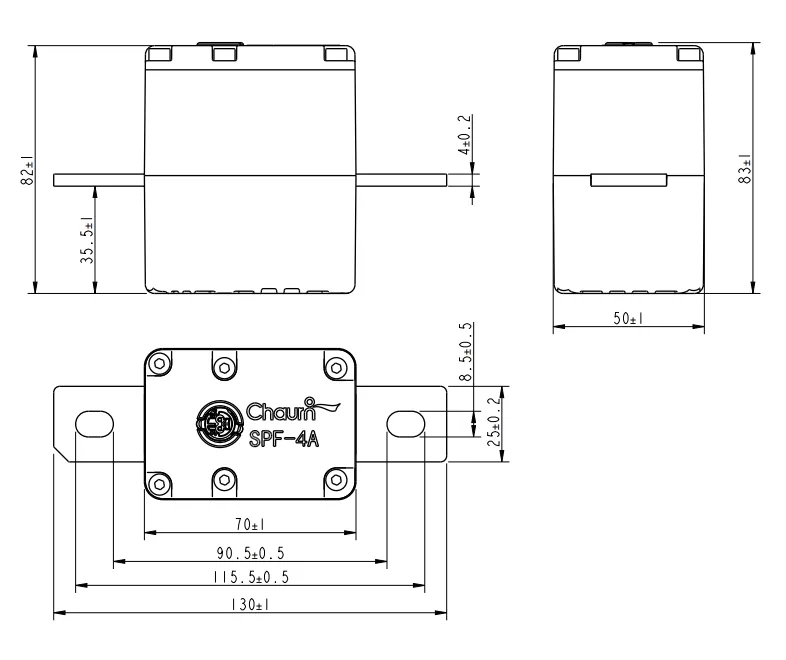

SPF‑4A Dual‑Trigger

Rated voltage: Up to DC 1000V

Rated current: 200-1000A

Breaking capacity: 1000V/16KA/40μH

Triggering current: ≥[email protected]

Triggered by an internal and external signal

Dual-trigger design enables both internal fault sensing and external BMS control for precise, safe battery isolation.

Pyrofuse Series

Breaking Capacity: 1.2kA – 16kA @ 32V–1000V DC

Rated Voltage Range: 32V – 1000V DC

Rated Current Range: 200A – 1000A

Click Get PDF Specs to access full engineering data.

| Models | Image | Rated Voltage | Rated Current | Size (mm) | Weight (g) | Trigger Method | Max. Breaking Capacity |

|---|---|---|---|---|---|---|---|

| SPF-1 |  |

DC150V | 300A | 30×22×42 | ≤60 | Triggered by external signal | 32V/2kA/60μH 150V/1.2kA/60μH |

| SPF-2 |  |

DC500V | 400A | 42×42×68 | ≤190 | Triggered by external signal | 400V/10kA/15μH 500V/5kA/20μH |

| SPF-2L |  |

DC930V | 400A | 42×42×63 | ≤180 | Triggered by external signal | 930V/12kA/15μH 500V/13kA/15μH |

| SPF-3 |  |

DC1000V | 400A | 50×50×79 | ≤230 | Triggered by external signal | 1000V/16kA/20μH |

| SPF-4A |  |

DC1000V | 200-1000A | 70×50×83 | ≤340 | Triggered by internal and external signal | 1000V/16kA/40μH |

Engineering Challenges? We Solve Them.

Can You Trust a One-Shot Safety Device?

A pyrofuse has no second chance.

To ensure consistent performance, we eliminate manual variation through fully automated assembly, combined with in-process inspection and statistical control on critical parameters.

The result is repeatable triggering behavior across production batches, not just on selected samples.

- Fully Automated Assembly & In-Line Inspection

- Controlled Trigger Element Characteristics

- In-Process Control on Critical Parameters

Can Your Project Afford Long Lead Times?

Fast iteration matters in both R&D and production.

We support short sampling lead times for early validation, and provide scalable manufacturing capacity to support volume ramp-up once the design is frozen.

Our supply model is built to align with engineering timelines, not disrupt them.

- Samples Ship in 3 Days

- Automated High-Volume Production

- Stable Quality & On-Time Delivery

What Happens If the Control Signal Is Unavailable?

When a single trigger path is not enough.

We support optional fail-safe pyrofuse architectures, where passive protective behavior can complement an active trigger signal under defined abnormal conditions.

This provides an additional layer of system-level protection when required by the application.

- Optional Active / Passive Trigger Architecture

- Fail-Safe Behavior Under Defined Conditions

- Application-Dependent Safety Design

Who We Are

Led by Industry Experts. Built on In-House Manufacturing & Validation.

Chauron Technology focuses on one thing: making pyrofuses that engineers can trust in high-energy DC systems.

We don’t position ourselves as a component reseller, but as a technology-driven manufacturer with direct control over design, validation, and production.

Our R&D and technical direction are led by Dr. Dai, a recognized expert and Standards Committee Member in China’s fuse industry. This background shapes how we design, test, and qualify our pyrofuse solutions — with clear safety margins and defined operating behavior, not assumptions.

Behind every product is our own infrastructure: two modern manufacturing facilities and an in-house CNAS-accredited laboratory. From automated production consistency to fault-level validation, critical performance is verified internally before it reaches your system.

For engineers, this means traceable design logic and test-backed performance.

For procurement teams, it means a factory-direct partner capable of supporting both development programs and long-term supply.

Why Choose Chauron?

01

We Help Shape Industry Standards

Our founder Dr. Dai plays a key role in shaping China’s fuse standards—positioning our solutions to meet future regulatory demands and streamline your path to certification.

- SAC/TC340 Member – Standardization Administration of China / Technical Committee 340 on Fuses

- Lead Author – GB/T Standard for Battery System Fuses

- Revision Leader – GB/T Standard for EV, PV Fuses

- CNAS Certified – China National Accreditation Service for Conformity Assessment

- CE, CCC, UL, TÜV Certified

- Compliant with IATF16949, ISO 45001, ISO 14001

02

Our Laboratory is CNAS-Accredited

Performing in-house testing and certification ensures fast, reliable, and fully verified fuse solutions—eliminating the need for external validation.

03

We Build with Automation

We operate two fully automated factories—ensuring consistent quality, stable processes, and flexible production for reliable, on-time delivery at any scale.

- Fully Automated – Precision-built for consistency and scale

- Flexible Production – Quickly adjust to different orders and custom requirements

- Dual Facilities – Redundancy and capacity to support urgent or parallel projects

04

We’re Nationally Certified

Officially recognized as a National High-Tech Enterprise—backed by strong R&D and innovation capabilities to ensure long-term reliability and trusted technical solutions.

- National High-Tech – Certified by China's Ministry of Science and Technology

- Innovation-Driven – Strong in-house R&D, continuous product advancement

- Reliable Supply – Long-term stability across development and delivery

Engineering FAQs — Before You Specify a Pyrofuse

Unlike passive fuses, a pyrofuse uses a triggered disconnection mechanism to isolate high-energy DC circuits within a defined time window. Proper trigger coordination and system integration are essential to ensure correct operation.

No. Dual-trigger or fail-safe architectures are available only for specific models and applications (for example, SPF-4A).

Pyrofuse configuration depends on system requirements and should be defined during the selection and design phase.

Currently, there is no dedicated UL or IEC standard specifically covering pyrofuses.

Our products are designed and validated based on applicable system-level requirements, material flammability standards (UL 94 V-0), and internal verification protocols.

In addition, selected models have been validated in automotive OEM and Tier-1 programs as part of customer-specific system evaluations.

Relevant test data and validation reports can be provided during technical evaluation.

Key inputs include DC system voltage, normal and fault current levels, circuit inductance, trigger strategy, and mechanical integration constraints. Providing complete system information enables accurate selection and validation.

Yes. We provide STEP files and dimensional drawings to support mechanical fit verification during the design stage, before sample release or ordering.

For standard models, samples are typically ready within 3 days. For application-specific adaptations, lead time may vary depending on design scope and validation requirements.

No. While pyrofuses are widely used in EV battery systems, they are also applied in energy storage, high-voltage charging, and industrial DC distribution systems where fast, controlled isolation is required.