In battery-based DC power systems such as electric vehicles, energy storage systems, and high-power industrial DC platforms, a deterministic, commandable, and ultra-fast disconnection is required to ensure system safety under emergency and fault conditions.

A pyrofuse (or pyrotechnic fuse) is a one-shot safety isolation device. When commanded, it uses a pyrotechnic actuation mechanism to physically break the busbar, rapidly isolating the battery from the rest of the system

Unlike conventional fuses and contactors, which require time for melting, contact separation, and arc extinction, a pyrofuse can establish electrical isolation by physically severing the conductor within a few milliseconds, often in under one millisecond.

In practice, a pyrofuse is installed in the battery’s main high-voltage current path, typically alongside the main contactors. It is activated by an electronic trigger signal from the control system (such as the BMS or a crash detection unit) to force an immediate physical disconnection when a hazardous condition is detected.

This rapid disconnection isolates the battery from the system. By doing so, it helps prevent fault conditions from escalating into thermal runaway or electric shock.

1. Internal Structure and Components

Chauron pyrofuse product overview

A pyrofuse consists of a specially designed current-carrying conductor integrated inside a sealed housing together with a pyrotechnic actuator.

Under normal operation, it conducts current as part of the battery’s main current path. When commanded by the control system, the initiator receives an electrical firing pulse, causing the pyrotechnic actuator to generate a powerful mechanical action that drives a cutting mechanism.

This mechanism physically severs the conductor, creating a rapid and irreversible electrical isolation between the battery and the rest of the system.

2. Operation and Triggering Mechanism

A pyrofuse is activated by an external electronic trigger signal. Typically the vehicle’s Battery Management System (BMS) or an airbag/crash control unit monitors for faults.

Upon detecting a severe overcurrent or an impact event, the controller issues a low-voltage pulse (on the order of 3–12 V for a couple of milliseconds) to a dedicated pyrofuse driver or squib igniter.

This pulse causes a spark in the initiator, igniting the pyrotechnic charge. In a matter of microseconds, the ignition generates gas pressure that drives the piston into the busbar.

The entire disconnect process is extremely fast: modern pyrofuse systems complete the break in less than 1 ms from trigger to open-circuit. (By comparison, an electromechanical contactor might take 5–10 ms or more.)

Some pyrofuse designs also include a self-triggering feature. In addition to an external signal, they contain integrated current sensing and will blow automatically if the current exceeds a set threshold (even without a crash command).

The Chauron SPF-4A is an example of a dual-trigger pyrofuse designed to support both externally commanded activation and current-based self-triggering for enhanced system-level safety.

This “dual-trigger” capability provides extra protection by ensuring that extremely high short-circuit currents are cut off immediately. Whether triggered by the BMS or by internal sensing, the result is the same: the battery is severed from the load or charger in a fraction of a millisecond, preventing further fault propagation.

3. Advantages Over Conventional Fuses and Contactors

Pyrofuses offer several key benefits compared to ordinary thermal fuses or mechanical contactors:

- Ultra-fast response – Pyrofuses interrupt current in well under 2 ms. This is typically an order of magnitude faster than the blow time of even a high-speed thermal fuse or relay. In an EV crash or hard short, this speed is critical to stop arc formation and thermal runaway before it starts.

- Zero-current disconnect – Unlike thermal fuses, a pyrofuse does not need a high current to melt; it can be blown on demand with no current flowing. This means it can act as an emergency kill switch (e.g. if sensors detect imminent battery failure), not just an overcurrent protector.

- Low-loss conduction – In its ready state, a pyrofuse behaves as a solid metal busbar, introducing negligible voltage drop and avoiding the thermal aging mechanisms associated with melt-type fuses under continuous load.

In summary, pyrofuses offer a combination of rapid isolation, current-independent actuation, and low-loss conduction that is difficult to achieve with conventional fuses or contactors alone. This makes them a natural choice for emergency and last-line protection in battery systems.

4. Integration in Battery Packs and DC Power Systems

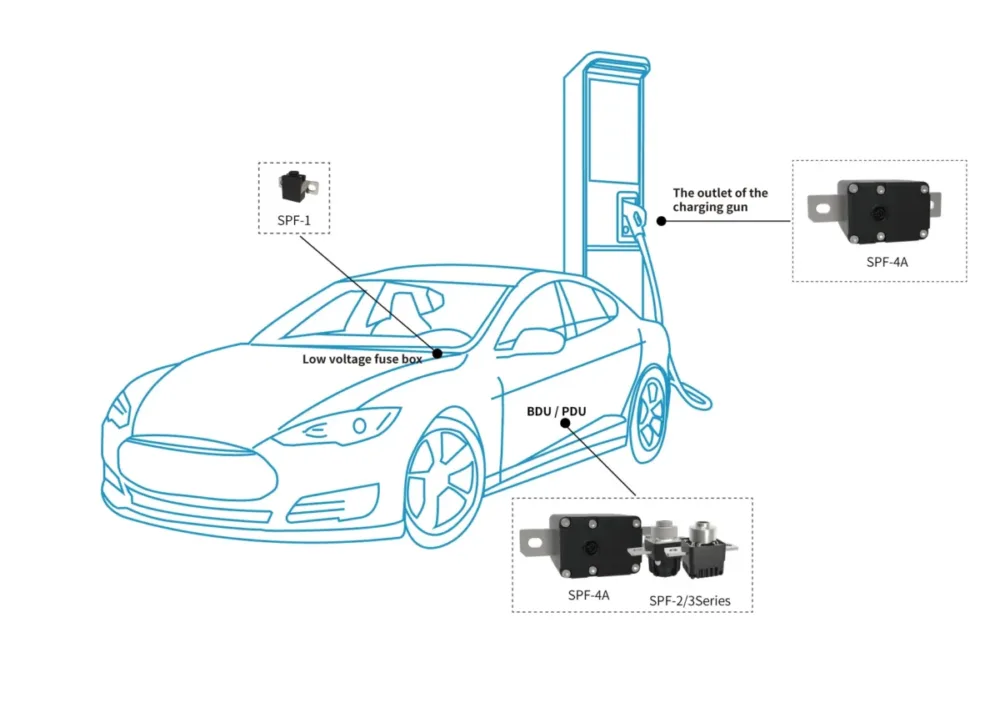

In EV and ESS applications, pyrofuses are typically integrated on the main DC power path within the battery disconnect unit (BDU) or power distribution unit (PDU), often in close association with the main contactors.

In a typical BDU architecture, the battery pack is connected and isolated by the main contactors during normal operation, while the pyrofuse remains in its conductive state as part of the HV bus structure.

Depending on the OEM and platform, the pyrofuse may be placed on one side of the HV bus (often HV+) or, less commonly, on both sides for specific safety architectures.

During a crash event or when an emergency isolation command is required, the pyrofuse provides a fast physical separation of the HV path, complementing the contactors and reducing reliance on their mechanical opening under extreme conditions.

In some designs it may also be used as part of the strategy for severe electrical fault isolation, depending on how the overall protection scheme is partitioned between fuses, contactors, and control logic.

Packaging-wise, the pyrofuse is commonly housed in the same enclosure as the contactors or within a companion module, and is integrated into the busbar layout to meet clearance/creepage and serviceability requirements.

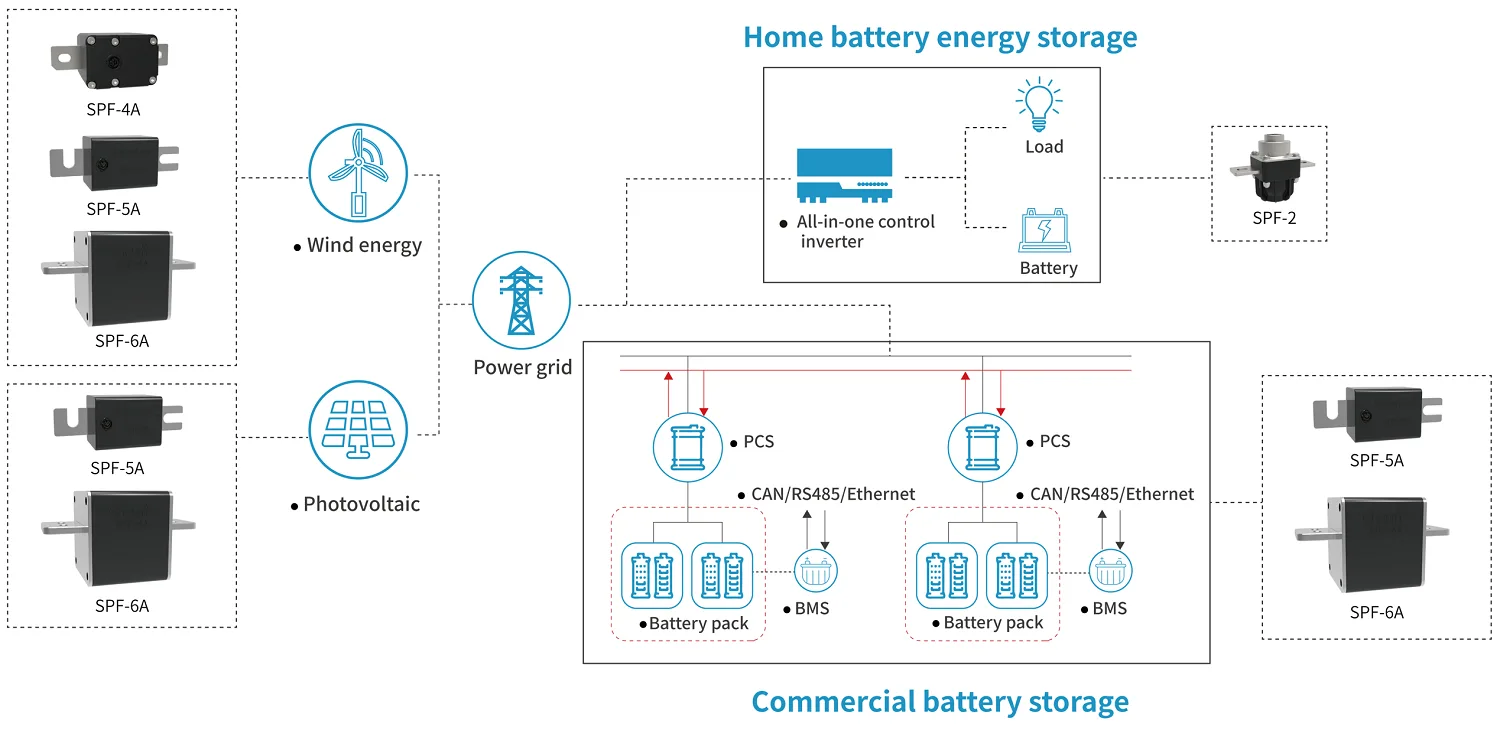

Beyond automotive BDUs, similar concepts appear in DC distribution—such as PV/ESS junction boxes, charger distribution units, and rack-level ESS protection—where a pyrofuse can be used as an emergency isolation element.

In many architectures, pyrofuses are used as part of a coordinated protection scheme alongside contactors, conventional fuses, and other protective devices, providing a reliable means of physical isolation when system safety requires it.

5. Typical Use Cases

- Electric and Hybrid Vehicles – Pyrofuses are widely used in modern EVs and are increasingly common in HEVs. In a collision or severe fault, they can rapidly isolate the battery, helping reduce the risk of fire and electric shock.

- Energy Storage Systems (ESS) – Large-scale battery banks for grid storage or solar installations often incorporate pyrofuses. These systems face similar risks of high currents and thermal runaway, so the fast disconnection capability is valuable for safety and compliance.

- Charging and Inverter Units – High-power chargers and DC/DC or AC/DC converters may include a pyrofuse on the high-voltage output line. If a downstream short or overheating is detected, the pyrofuse can rapidly disconnect the source.

- Aerospace and Military – High-voltage aerospace systems (e.g. avionics, drones, satellites) sometimes explore pyrofuse technology. The one-shot nature is a drawback, but the compact size and speed are attractive for emergency disconnects in strict isolation requirements. Some aerospace standards would require rigorous qualification. However, the one-shot, non-resettable nature of pyrofuses is often a significant concern in aerospace applications, necessitating rigorous qualification and redundancy.

In summary, anywhere an HV battery or bus needs ultra-rapid isolation, pyrofuses are considered. This spans electric cars and buses, industrial forklifts and AGVs, solar/generator hybrid sites, uninterruptible power supplies, and more.

Pyrofuse in Energy Storage System

6. Key Performance Metrics

Pyrofuse Product Specifications

| Models | Image | Rated Voltage | Rated Current | Trigger Method | Max. Breaking Capacity |

|---|---|---|---|---|---|

| SPF-1 |  |

DC150V | 300A | external signal | 32V/2kA/60μH 150V/1.2kA/60μH |

| SPF-2 |  |

DC500V | 400A | external signal | 400V/10kA/15μH 500V/5kA/20μH |

| SPF-2L |  |

DC930V | 400A | external signal | 930V/12kA/15μH 500V/13kA/15μH |

| SPF-3 |  |

DC1000V | 400A | external signal | 1000V/16kA/20μH |

| SPF-4A |  |

DC1000V | 200-1000A | internal and external signal | 1000V/16kA/40μH |

When evaluating or selecting a pyrofuse, engineers focus on several critical parameters:

- Voltage and Current Rating – Pyrofuses are specified for the maximum DC voltage (typically 300–1000 V for EV/ESS) and continuous current (tens to hundreds of amperes) of the application. For example, common automotive pyrofuses are rated for 400–800 V systems with continuous currents of several hundred amps.

- Interrupting (Breaking) Capacity – This is the maximum fault current the device can safely clear. High-end pyrofuses are designed for extreme fault levels: on the order of 10–20 kA at 500–800 V. Engineers ensure the interrupt rating exceeds the worst-case short-circuit current of the battery pack.

- Response Time – How quickly the fuse actually opens after the trigger signal. Pyrofuses are typically extremely fast: measured end-to-end (including detection and firing) in the sub-millisecond range. The actuation time of the squib itself is approximately 0.1–0.5 ms.

- Endurance and Lifetime – While a pyrofuse is single-use, it must survive years of standby and some mechanical stress. Relevant specs include insulation resistance (e.g. >100 MΩ at rated voltage) and environmental ratings (vibration, humidity, shock). Many devices are qualified to automotive standards (e.g. AEC-Q200). Also considered are size, weight, and thermal characteristics.

In practice, a pyrofuse datasheet might list: “Interrupts 20 kA @ 800 V in <1.5 ms; continuous current 400 A; opens at <300 A with internal trigger; leakage <100 μA” – these kinds of numbers ensure the fuse handles both normal load and fault scenarios.

7. Market Adoption and Manufacturers

Pyrofuse technology has seen rapid adoption in recent years. Today’s major circuit protection companies all offer pyrotechnic-disconnect products. For example:

Chauron – Offers a pyrofuse portfolio for EV and ESS applications, with products rated up to 1000 V DC, continuous current levels up to 1000 A, and breaking capacities up to 16 kA. Selected models support dual-trigger activation to enable rapid physical isolation in battery systems.

- Eaton (Bussmann) – Offers an entire series of EV pyrofuses (both active- and dual-trigger types) rated for 400–800 V systems. Their catalogs quote specs like <1.5 ms trip time and 20 kA fault rating.

- Mersen – Sells hybrid “DC contactor + pyrofuse” modules (XP series) designed to complement contactors in battery packs. These are integrated HV fuse solutions for EV battery packs (500–1000 V).

- Littelfuse – While historically a fuse maker, Littelfuse has introduced pyrofuse trigger circuits and sensors. Their CH1B050P pyrofuse driver chip, for instance, can ignite a pyrofuse in microseconds upon overcurrent. Littelfuse also markets high-voltage fuses and related components for EV safety.

- Sensata (Crane) – The Sensata PyroFuse (formerly by Crane/Pulse) is one of the earliest EV pyrofuse products, capable of kA-level interruption in <1 ms. Sensata continues to supply pyro-disconnects, especially for OEMs.

- Autoliv / Daicel – Daicel (which owns Autoliv’s pyro business) produces the “VoltBreaker” and PDD series pyrofuses for automotive use. For example, Daicel’s PDD5 supports up to 900 VDC and 20 kA disconnection.

Others – Companies like Mitsubishi / PEC (Japan), Eaton, and various Tier-1 automotive electronics firms also develop or OEM pyrofuse solutions.

Market research notes strong growth in the pyrofuse segment, driven by global EV regulations and trends. In practice, virtually all new BEVs (battery electric vehicles) now include a pyrofuse or equivalent high-speed disconnect in their BMS.

Conclusion

In summary, a pyrofuse is a fast-acting, one-time isolation device for DC power systems, particularly in battery-based architectures where rapid physical disconnection is required for safety.

It consists of a metal busbar, a piston mechanism, and a pyrotechnic initiator, all packaged within a sealed housing designed to control arc formation during disconnection.

Triggered by an electronic command (from the BMS, airbag controller, or internal sensor), it isolates the DC circuit within the sub-millisecond to millisecond range.

This combination of fast isolation and high fault-interruption capability makes pyrofuses well suited for use in EV battery packs, energy storage systems, and other battery-based DC applications.

Engineers integrate them alongside contactors in Battery Disconnect Units (BDUs) and Power Distribution Units (PDUs) to provide redundant fault protection.

As electric vehicle and ESS usage grows, pyrotechnic fuses have become a standard part of the safety toolkit, supported by major manufacturers (Chauron, Eaton, Littelfuse, Mersen, Sensata, etc.) and certified to rigorous safety standards.

With high fault-interruption capability and fast response, pyrofuses serve as a critical “last line” of isolation in modern battery-based DC power systems.